This guide should only be used to help you as a suggested way to fix your equipment. They are not intended to be the only way to do. Its your responsibility if any damage occurs. If you are not sure of any part of these instructions, feel free to send us an email, we would be happy to help.

There are many small pieces involved with this. So proceed with caution, use common sense and proper safety measures.

Please be aware that we are not responsible for any damages that happen. By using this guide you understand that we have made this only to make installation easier for you. However, do to the age of these things, every gauge cluster has been through a different life.

TOOLS NEEDED:

– Assortment of philips screw drivers

– needle nose pliers

– flat screw driver

– a little patience

TIME NEEDED:

– About 45 mins. This is something that takes patience. You’re dealing with lots of tiny pieces.

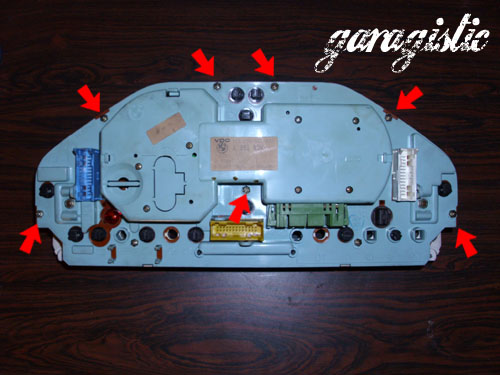

STEP 1

Remove the 9 Philips screws in the back of your gauge. When placed down, be careful not to brake the tabs!

STEP 2

When removing rear panel, take note of the two lower tabs and be sure to pull straight up or damage to connectors inside may happen.

STEP 3

Remove the 4 Philips screws that hold the odometer in place. Before you try to take out the cluster, do not forget the connector at the bottom. There are tabs that hold it in place. Once this is out you can pull straight out because there are connectors holding. DO NOT BEND! We found its best if you hold the cluster as it was placed in the car that way it doesn’t fall out.

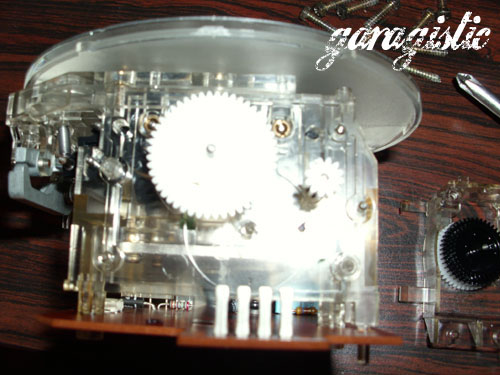

STEP 4

When odometer is out, you will see the gears on the side. There should be three. See the damage.

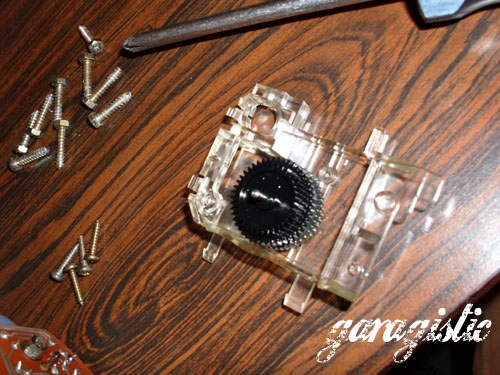

STEP 5

There are two screws holding a clear cover over the gears. Remove them.

STEP 6

The gears can then be replaced in the order they are taken out. They fit in an interlocking stacking setup. Notice that the gears are very soft and will fall apart as you try to remove them. NOTE: There is a brass bushing on the smaller 12 tooth gear. Its on the shaft and needs to be removed to install the new gear. You do not need this bushing with the new gear. DO NOT TRY TO PULL THE BUSHING OFF WITH ANY TOOLS AS THIS WILL DAMAGE THE MOTOR. Best way is to use a pair of pliers and lightly squeeze the bushing from one side, then the other. Then it ill slip right out. Do not use too much force!

Dont forget to install out spacer to keep the gears spaced correctly. DO NOT PUSH IT ALL THE WAY DOWN AGAINST THE GEAR. THIS WILL CAUSE THE GEARS TO BE PINCHED AND NOT BE ABLE TO MOVE!

.jpg)

STEP 7

Put together in reverse order. Be sure you have gotten all the old pieces of the gears out so you have no future problems. Before closing everything up be sure to run the gears by hand to make sure everything is right and working correctly.

ENJOY! No more guessing when the next oil change is!